Blog

Understanding tmt Cat6 Cable Color Codes: Insights from Fahad Cables Industry FZE uae

Introduction to Cat6 Cables

Cat6 cables, classified under the category of Ethernet cables, play a pivotal role in networking by facilitating high-speed data transmission. These cables are designed to support data rates of up to 10 Gbps for short distances of up to 55 meters, making them a preferred choice for modern networking environments. The evolution of Cat6 cables from earlier standards such as Cat5 and Cat5e marks a significant advancement in networking technology. The enhancements in design and construction address the increasing demands for higher bandwidth and faster data communication. The tmt Cat6 Cable Color Codes are crucial for understanding their functionality and application.

The importance of Cat 6 cables cannot be overstated, as they serve as the backbone of both residential and cat 6 colours commercial networks. With the surge in data-heavy applications, network cable colors including streaming services, cat 6 wire color code online gaming, and cloud computing, the need for reliable and efficient cabling has lan color code become imperative. The quality of materials used in the manufacturing of Cat6 cables directly influences their performance; factors such as insulation, shielding, and connector types can greatly affect data transmission speeds and overall reliability.

Familiarity with the tmt Cat6 Cable Color Codes is essential for anyone involved in network installation or maintenance. These codes ensure proper connectivity and minimize interference, allowing for seamless communication within various networking infrastructures.

Understanding the tmt Cat6 Cable Color Codes helps technicians to quickly identify and troubleshoot cable connections, crucial in managing extensive networks. Following these color codes can prevent miswiring and ensure efficient data transmission.

In comparison to earlier cable standards, Cat 6 cables introduce improved specifications that help reduce crosstalk and interference, enabling more stable and faster connections. data cable color code The enhancements include tighter twists ethernet color codes in the wire pairs, which minimize electromagnetic interference from external sources. The transition from Cat5 to Cat 6 not ethernet colour code only provides better performance but also future-proofs networks, accommodating advancements in technology and usage. As industries increasingly rely on robust networking infrastructures, understanding the capabilities and importance of Cat 6a cables is vital for optimal performance.

Overview of Fahad Cables Industry FZE

Fahad Cables Industry FZE, established in the early 2000s, has carved a significant niche in the cable manufacturing sector through its unwavering commitment to quality and innovation. Located in the United Arab Emirates, the company has positioned itself as a key player in the Arabian market, specializing in the production of a wide array of cables including power, telecommunication, and control cables, among others. The company’s history is marked by a strong focus on technological advancement, enabling it to consistently meet and exceed industry standards.

The mission of Fahad Cables Industry FZE revolves around providing high-quality cabling solutions that cater to the growing demands of various sectors, including construction, telecommunications, and industrial applications. By prioritizing customer satisfaction and operational excellence, the company has succeeded in building a robust reputation in the market. Ensuring compliance with international quality standards has further established Fahad Cables as a trusted name among clients and partners alike.

ethernet cable color code

Among the key achievements of Fahad Cables Industry FZE is its ability to attain multiple certifications from renowned quality assurance organizations, which reinforces its credibility in the cable manufacturing industry. Furthermore, the company’s state-of-the-art production facilities are equipped with advanced machinery, allowing for highly efficient production processes that maintain high quality while keeping up with demand. This capability has enabled Fahad Cables to successfully supply large-scale projects, both regionally and internationally. brown wire crossover cable green wire ethernet cable color orange wire orange white network connectivity reliable network

Fahad Cables Industry FZE boasts a diverse range of products, demonstrating its expertise in manufacturing solutions tailored to specific requirements across various industries. ethernet patch cable color code By continuously investing in research and development, the company remains at the forefront of innovation, ensuring its position as a leader in the cable industry. Such dedication to excellence and customer-centric values secures Fahad Cables Industry FZE’s standing as a premier manufacturer in its field. Cat 6 Cable Color Codes

The color codes play a vital role in ensuring the integrity of the data transmitted through the tmt Cat6 Cable Color Codes. An incorrect wiring scheme can lead to decreased network performance and increased latency.

Understanding Cable Color Codes

The significance of color coding in networking cables, including Cat6, is paramount for ensuring both organization and proper connectivity. The color codes serve as a visual guide, helping technicians and network engineers to correctly wire connections and maintain an orderly system. In telecommunications and data networking, miswiring can lead to various issues, such as signal loss, interference, and overall network dysfunction. Thus, adhering to established color code standards is essential in preventing these potential pitfalls. Cat 6 Cable Color Codes

Utilizing the tmt Cat6 Cable Color Codes not only aids in compliance with established standards but also enhances the overall performance of networking setups.

Correctly following the tmt Cat6 Cable Color Codes during installation is essential for ensuring that networks operate efficiently and reliably.

For anyone working with networking cables, mastering the tmt Cat6 Cable Color Codes is indispensable for achieving optimal outcomes in data transmission.

Each wire within a Cat6 cable is assigned a specific color to ensure that connections between devices are made correctly. The standard color scheme typically follows the T568A or T568B wiring configurations. For example, in the T568B standard, cat 5 colour code the first pair consists of white/orange and orange wires, while the second pair comprises white/green and green wires. The third and fourth pairs follow suit with white/blue and blue, and white/brown and brown, respectively. Understanding these codes allows for swift identification and troubleshooting of cable connections, which is crucial in managing extensive networks.

The primary purpose of color codes in networking cables extends beyond organization. It plays a vital role in ensuring the integrity of the data transmitted. An incorrect wiring scheme can lead to decreased network performance and increased latency. This can cause significant disruptions in environments that rely heavily on wireless connectivity and prompt data transfers. Therefore, familiarity with these codes is not just advantageous for efficient organization but is imperative for maintaining a reliable connectivity standard across networking environments. By employing the correct color coding practices, professionals can mitigate the risks of network issues significantly.patch cord color code

Cat6 Cable Color Code Standards

Cat6 cables are essential components in modern networking, serving as a medium for transmitting data between devices. A critical aspect of these cables is their standardized color codes, ethernet connector color code primarily defined by two wiring schemes: T568A and T568B. Understanding these standards is vital for anyone involved in network installation or maintenance, as it ensures proper connectivity and minimizes interference.

The T568A wiring scheme employs a specific combination of colored wires for each pair, facilitating efficient data transmission. In this scheme, the color codes are as follows: Pin 1 (white/green), Pin 2 (green), Pin 3 (white/orange), Pin 4 (blue), Pin 5 (white/blue), Pin 6 (orange), Pin 7 (white/brown), and Pin 8 (brown). The choice of green and orange for the pairs emphasizes compatibility with older wiring standards. brown wire crossover cable green wire ethernet cable color orange wire orange white network connectivity reliable network

Introduction to ELV Cables

Extra Low Voltage (ELV) cables play a critical role in modern electrical systems, serving various functions across residential, commercial, and industrial sectors. Defined as cables that operate at a voltage of less than 50 volts AC or 120 volts DC, ELV cables are designed to ensure safe and efficient transmission of electrical power for low-voltage applications. Their significance is underscored by their wide-ranging applications, encompassing data communication, security systems, lighting control, and even audio-visual functionalities.

There are several types of ELV cables, each tailored for specific uses. For instance, twisted pair cables are commonly employed in structured cabling systems for data networking. Coaxial cables, on the other hand, are extensively used for transmitting both television and internet signals. Additionally, alarm cables are fundamental for alarm and safety systems, while fire alarm cables are engineered to maintain functionality in emergency situations. The selection of the appropriate ELV cable type is crucial, as it directly impacts the reliability and integrity of the overall electrical system.

The importance of utilizing high-quality ELV cables cannot be overstated, as they contribute to enhancing the efficiency and safety of electrical installations. Poor-quality cables can lead to various issues such as signal loss, increased resistance, and potential fire hazards. This scenario underscores the necessity of partnering with a reputable manufacturer, particularly in the UAE, where the demand for robust electrical solutions is consistently growing. A leading manufacturer not only provides quality assurance but also offers comprehensive support, ensuring that clients can make informed choices tailored to their specific needs and regulatory compliance. Overall, understanding the various types and applications of ELV cables is essential for sustainable and safe electrical infrastructure development.

By understanding the tmt Cat6 Cable Color Codes, technicians can ensure higher levels of network reliability and performance.

Using the correct tmt Cat6 Cable Color Codes during installation leads to improved organization and easier troubleshooting in future maintenance.

Moreover, the tmt Cat6 Cable Color Codes help prevent connectivity issues and contribute significantly to maintaining system integrity.

The Role of Manufacturers in the Cable Industry

Manufacturers play a pivotal role in the cable industry, significantly influencing the overall quality and reliability of cable products. In a market where electrical performance and safety are paramount, the production process adopted by manufacturers such as those in the UAE has a direct effect on the end product. This includes everything from material selection to final assembly.

The manufacturing process for cables typically encompasses several stages, including material procurement, extrusion, stranding, and insulation. Each of these stages requires precision and attention to detail. Manufacturers ensure that only high-quality materials are sourced; this not only impacts durability but also the electrical characteristics of the cables. Furthermore, the integration of advanced technology during production enables manufacturers to craft cables that meet stringent industry standards.

Conversely, the T568B wiring scheme is also widely used and slightly alters the pin assignments. In this setup, the colors used are: Pin 1 (white/orange), Pin 2 (orange), Pin 3 (white/green), Pin 4 (blue), Pin 5 (white/blue), Pin 6 (green), Pin 7 (white/brown), and Pin 8 (brown). The primary distinction between T568A and T568B lies in the arrangement of the wiring pairs, impacting how Ethernet connections are established.

When making connections, it is crucial to adhere to the chosen wiring standard consistently throughout the network to avoid potential performance issues. Both T568A and T568B yield similar performance characteristics, but uniformity ensures that all devices on the network can communicate seamlessly. Thus, understanding these color codes is not only fundamental for installation but also for troubleshooting in future network maintenance.

Benefits of Using Correct Color Codes

The usage of correct color codes in Cat6 cable installation brings numerous advantages that can significantly enhance network performance and reliability. One of the primary benefits is improved organization within cable management systems. When technicians utilize standardized color codes during installation, it becomes easier to identify the purpose of each cable, facilitating effective organization. This structured approach is particularly beneficial in environments with multiple cables, such as data centers, where the risk of confusion can lead to costly downtime or errors.

Another benefit of adhering to correct color codes is the ease of troubleshooting. Network issues can arise due to various reasons, including faulty connections or equipment malfunctions. When color codes are followed accurately, technicians can quickly trace back the network setup to identify the source of the problem. For instance, if there is a connectivity issue, a technician can swiftly check the specific colored wires associated with a particular data line rather than having to sift through unsystematically arranged cables. This efficiency not only saves time but also minimizes potential interruptions to critical operations.

Additionally, using the correct color codes contributes to reducing the risk of connectivity issues. Cable mismanagement or incorrect installations can lead to cross-talk, decreased network speeds, or complete failures in connectivity. Properly color-coded wiring ensures that pairs are connected according to manufacturer specifications, reducing the likelihood of signal degradation. In practical examples, organizations that adhered to color-coding conventions during their installations noted a marked reduction in network errors, thereby enhancing overall productivity. The advantages of using correct color codes extend beyond mere aesthetics; they represent a foundation for reliability and efficiency in network infrastructure.

Manufacturing Process and Quality Control at Fahad Cables

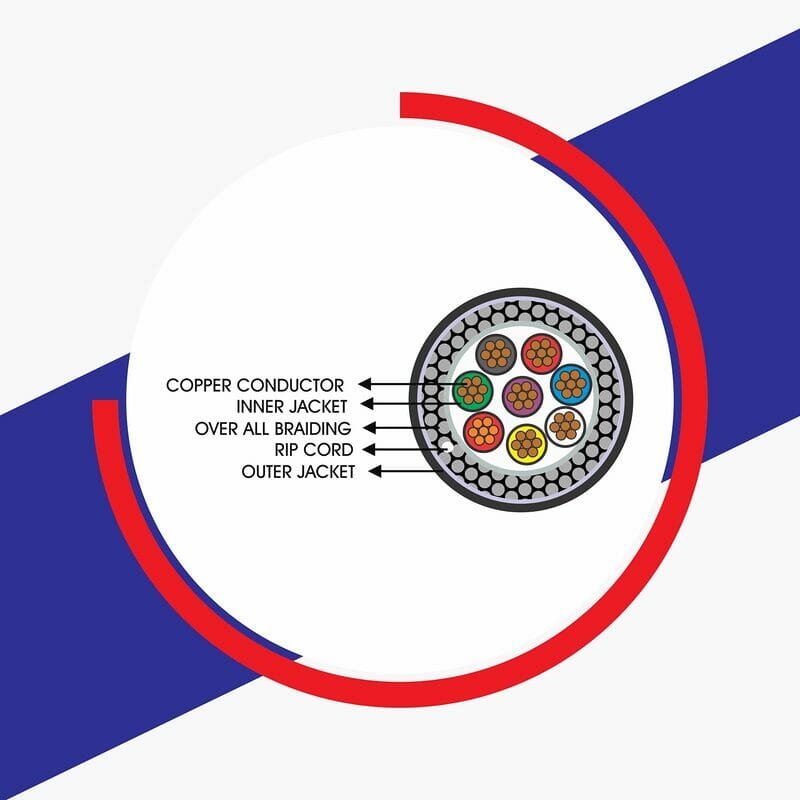

The manufacturing process of Cat6 cables at Fahad Cables Industry FZE is meticulously designed to ensure the highest quality standards. The initial phase involves careful material selection, where premium-grade copper conductors are chosen for their excellent conductivity and performance. The insulation materials, typically made from high-density polyethylene, are selected based on their durability and resistance to electromagnetic interference. This selection process is critical, as the quality of these materials directly influences the cable’s performance and longevity.

Following material selection, the production techniques employed at Fahad Cables are state-of-the-art. The copper conductors are carefully twisted into pairs, a ethernet color code process that minimizes crosstalk and enhances the overall transmission quality. This twisting technique is fundamental in maintaining the integrity of the signal, ensuring that the Cat6 cables provide high-speed data transfer capabilities. After the twisting, each cable undergoes a series of tests to assess its electrical characteristics, ensuring compliance with industry standards.brown wire crossover cable green wire ethernet cable color orange wire orange white network connectivity reliable network

Quality control is an integral part of the manufacturing process at Fahad Cables. The company implements rigorous quality assurance protocols at multiple stages of production. Each batch of Cat6 cables is subjected to comprehensive testing procedures, including signal loss tests and performance evaluations under various environmental conditions. Additionally, random samples from each production lot are pulled for more exhaustive analysis, assessing factors such as cable flexibility, durability, and resistance to external influences.

Incorporating feedback loops within the manufacturing process allows Fahad Cables to continuously refine its techniques and material choices. This commitment to quality not only ensures that each Cat6 cable meets the established performance benchmarks but also aligns with the evolving demands of the telecommunications industry. Overall, this comprehensive approach to manufacturing and quality control ensures that Fahad Cables remains a reliable choice for high-performance networking solutions.

Unraveling the World of Ethernet Data Patch Cords by TMT Global Technology Ltd UK

Introduction to Ethernet Data Patch Cords

Ethernet data patch cords are integral components of modern networking systems, serving as the backbone for data transmission across local area networks (LANs). These cables enable connectivity between various devices, such as computers, routers, and switches, facilitating seamless communication and data transfer. The necessity for reliable and efficient connections underscores the importance of Ethernet patch cords in both residential and commercial settings.

In conclusion, the tmt Cat6 Cable Color Codes not only simplify installations but also serve as the foundation for reliable and efficient networking solutions.

A typical Ethernet patch cord consists of two main components: the cable itself and the connectors at either end. The cables are usually made from twisted pairs of copper wires, which help reduce electromagnetic interference and ensure high-speed data transmission. The connectors, typically RJ45 plugs, are designed to fit securely into the ports of networking devices, providing a stable connection. The specifications of these cables vary, with categories ranging from Cat5e to Cat6a and beyond, each offering different capabilities regarding bandwidth and data rate.

The categorization of Ethernet cables is vital for understanding their applications. For instance, Cat5e cables are commonly used for standard internet connections and support data speeds of up to 1 Gbps. In contrast, Cat6 cables are suitable for more demanding environments, capable of handling speeds up to 10 Gbps over short distances. Additionally, the advancement of technology has led to the emergence of shielded Ethernet cables, designed to further mitigate interference and enhance performance in challenging environments.

In summary, Ethernet data patch cords play a crucial role in establishing effective networking solutions. Their designs, including the choice of cables and connectors, significantly influence the quality and speed of data transmission, making it essential to select the appropriate type for specific networking needs.

Incorporating the tmt Cat6 Cable Color Codes into your installation strategy enhances both the reliability and efficiency of your network.

Ultimately, mastering the tmt Cat6 Cable Color Codes is essential for anyone aiming to achieve excellence in network management and performance.

The Role of TMT Global Technology Ltd in Manufacturing

TMT Global Technology Ltd is a prominent entity in the telecommunications and networking industry, specializing in the manufacturing of Ethernet data patch cords. Established in the UK, the company has built a solid reputation over the years, underpinned by its commitment to quality and innovation. TMT Global Technology Ltd’s history is marked by a continuous pursuit of excellence, positioning it as a leader in technological advancements within the sector.

With a deep understanding of networking requirements and the evolving demands of global connectivity, TMT Global Technology Ltd has leveraged its expertise to produce high-performance Ethernet data patch cords. The company emphasizes rigorous testing protocols during the manufacturing process, ensuring that each product meets international standards for reliability and efficiency. By adopting cutting-edge technologies and employing skilled professionals, TMT Global Technology Ltd consistently delivers products that cater to a diverse clientele, from small businesses to large enterprises.

Moreover, TMT Global Technology Ltd’s strategic focus on quality control has played a pivotal role in enhancing its reputation within the industry. The company has implemented a comprehensive quality management system that involves regular assessments and evaluations at various stages of production. This not only ensures the durability and functionality of Ethernet data patch cords but also builds trust among customers, who increasingly rely on TMT’s products for their networking needs.

In recent years, TMT Global Technology Ltd has expanded its presence in the global market, reflecting its commitment to innovation through constant research and development. The company recognizes the importance of adapting to emerging trends, thus evolving its product offerings to meet the dynamic needs of its clients. As such, TMT Global Technology Ltd remains a key player in the Ethernet data patch cords manufacturing landscape, distinguished by its dedication to quality and customer satisfaction.

Conclusion and Best Practices

In summary, understanding the color codes associated with Cat6 cables is critical for anyone involved in networking, telecommunications, or systems installation. The use of standardized color coding not only facilitates the installation process but also enhances the ease of troubleshooting when issues arise. By adhering to the T568A and T568B wiring standards, technicians can ensure that the cables are wired correctly, promoting optimal performance of the networks they support.

To maximize the efficiency and reliability of your Cat6 installations, several best practices should be considered. First, always verify the wiring standards before commencing with the installation. A consistent approach, whether it’s T568A or T568B, is essential for maintaining the integrity of the network. Second, labeling cables is highly recommended; this practice helps in identifying connections quickly, thereby reducing downtime during maintenance or troubleshooting procedures.

Additionally, avoid exposing your Cat6 cables to excessive cat6 cable color order tension, heat, or interference from other electrical devices, as these conditions can degrade performance. Regular inspections of installed cables can also aid in preemptively identifying potential issues, ensuring that minor problems do not escalate into major complications.brown wire crossover cable green wire ethernet cable color orange wire orange white network connectivity reliable network

Incorporating proper installation techniques, understanding the significance of color codes, and following established best practices will contribute to the longevity and reliability of your Cat6 cables in any networking environment. The insights provided here aim to equip you with the knowledge needed to confidently tackle installation and maintenance tasks, ultimately fostering efficient communication networks.